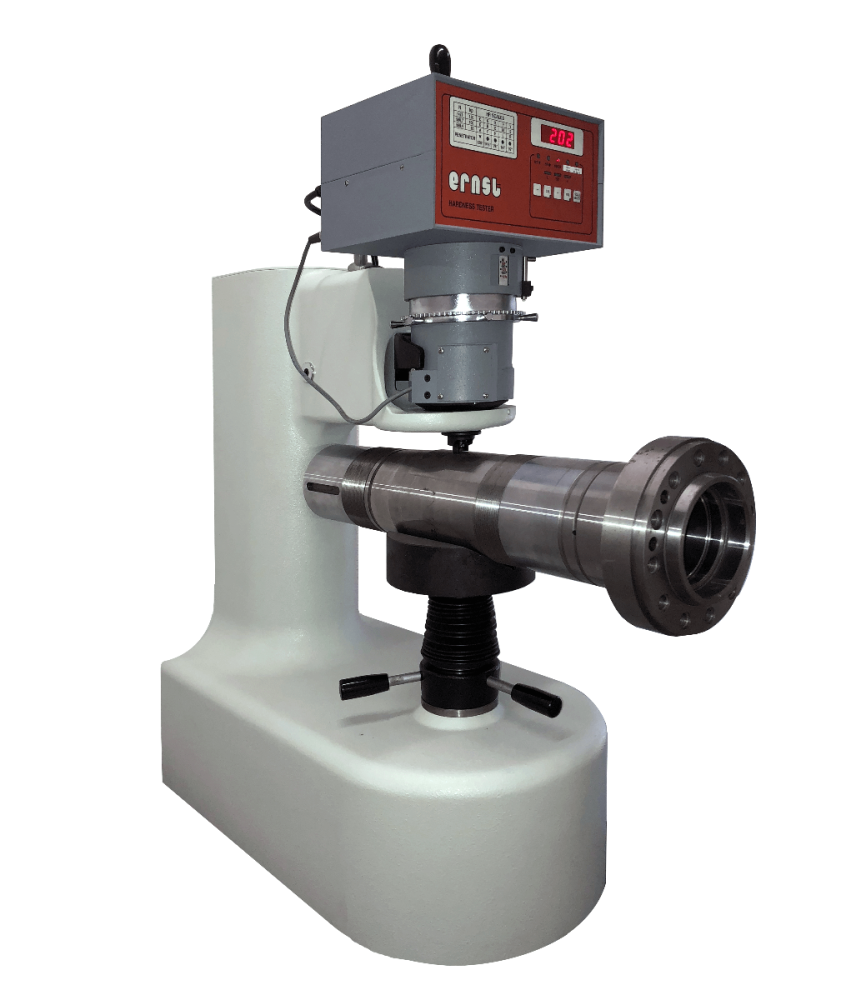

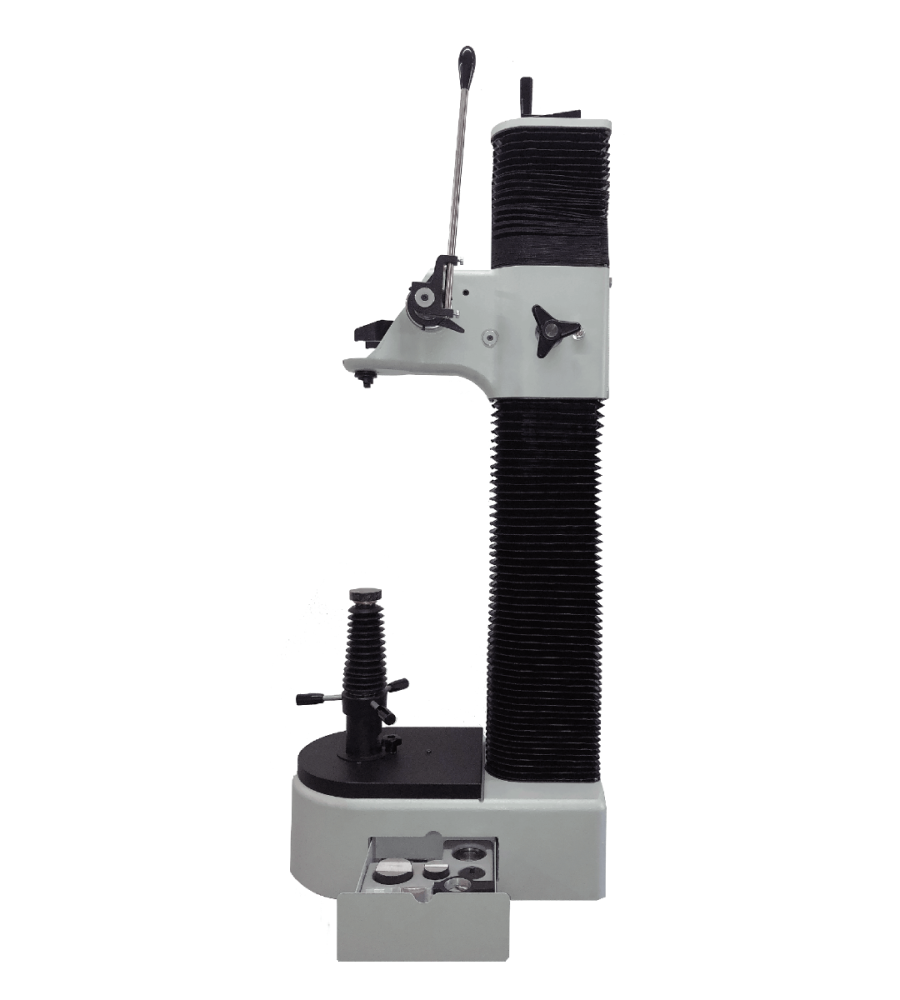

AT130 Bench Hardness Tester: Rockwell Precision and Speed

The AT130 bench hardness tester, based on the Rockwell principle per DIN and ASTM standards, ensures precision by eliminating the influence of material deflections. Measurement is taken directly on the sample surface, optimizing preparation.

Features and Benefits:

- Precision and Speed: Tests completed in just 2 seconds using the Rockwell principle.

- Spring Load System: Reliable measurements, insensitive to deflections.

- International Compliance: Complies with UNI, ISO, DIN, and ASTM standards.

- Optimized Productivity: One lever movement equals one test.

- Robustness: Ideal for critical environments with dust and vibrations.

The world-famous AT130 hardness tester, sold globally since the 1970s, is also available in a semi-automatic version. It provides precision and speed in all conditions, delivering results in just 4 seconds. Designed by Cisam-Ernst, it is a reliable and accurate instrument, ensuring high durability even in the most challenging conditions.