Ernst's MTR X Hardness Tester: An Innovative Solution for Metal Hardness Testing

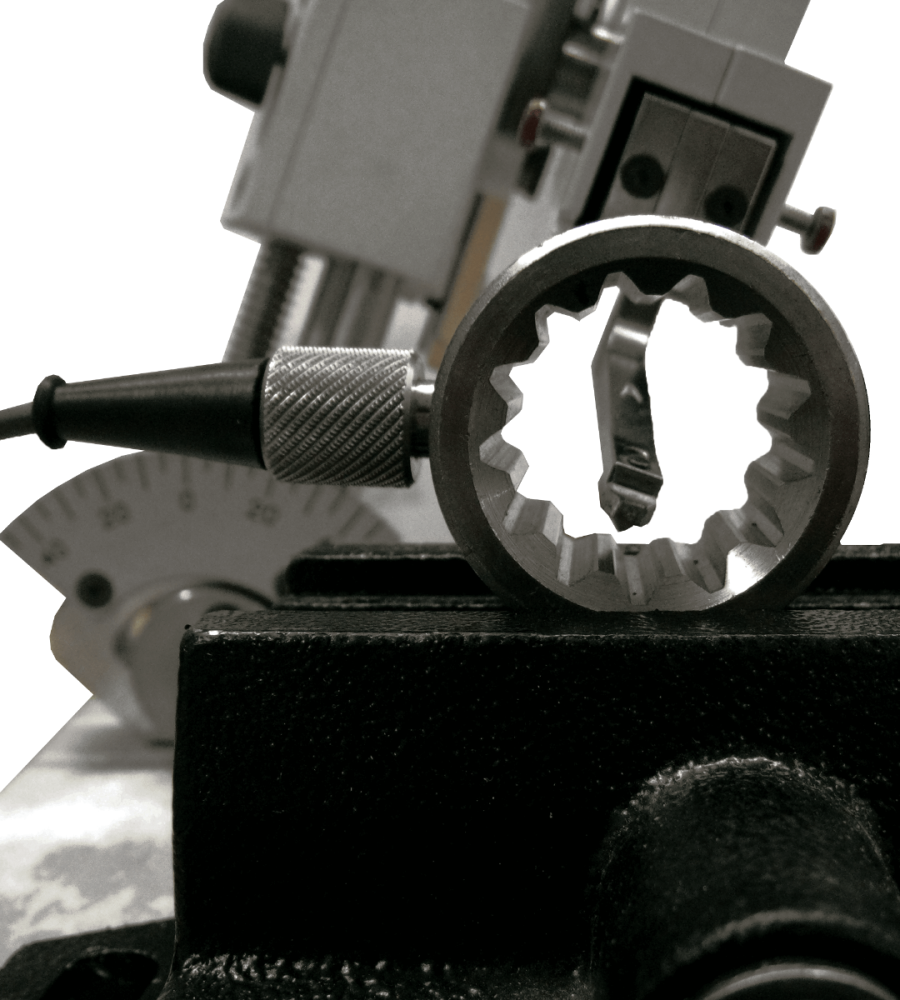

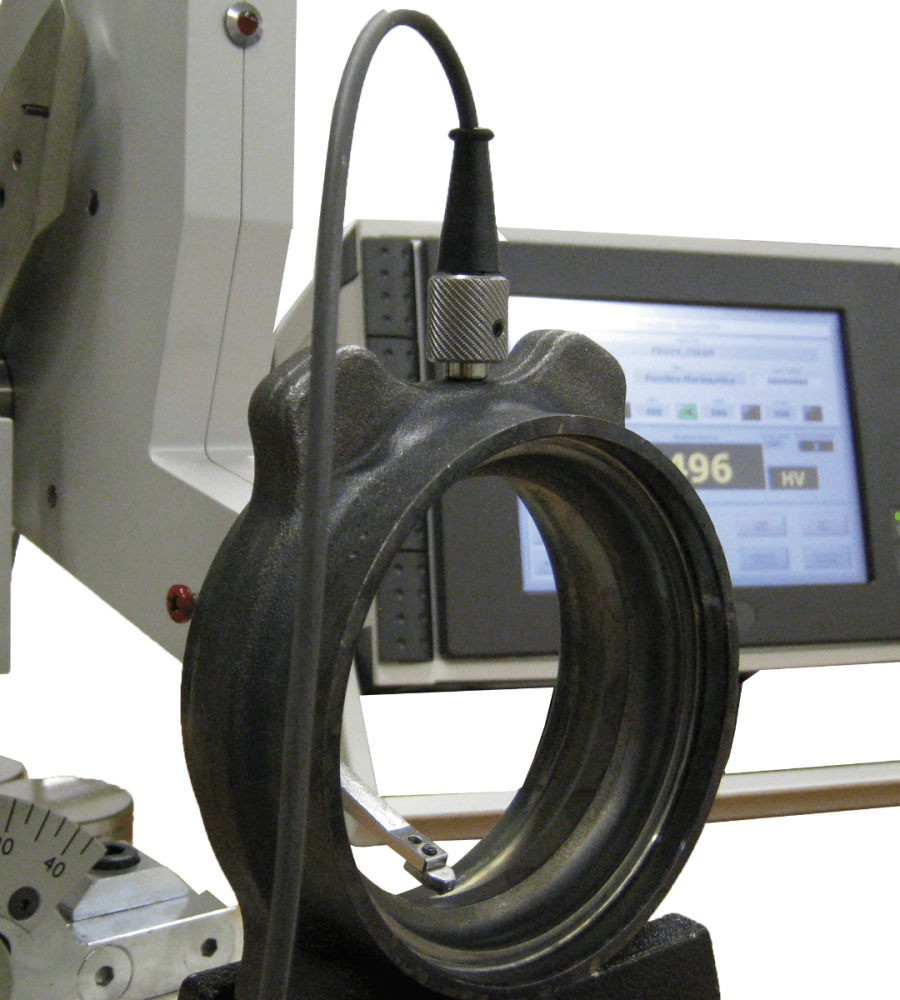

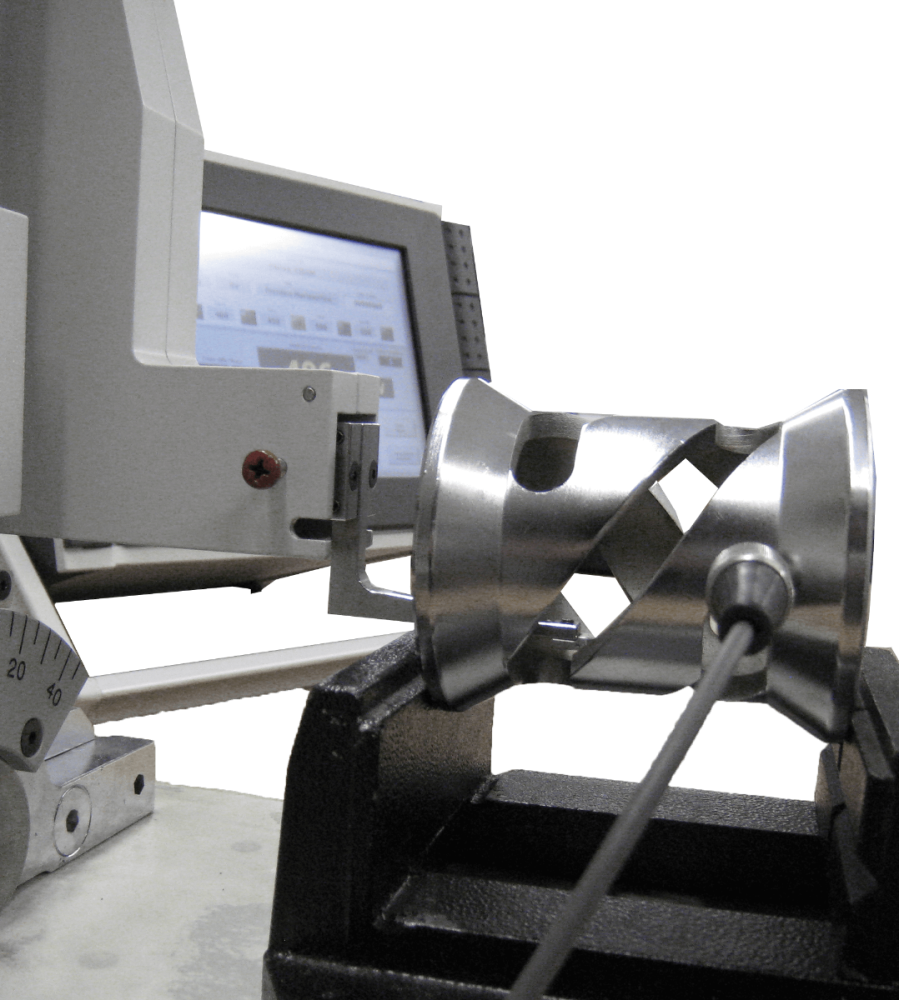

Ernst's MTR X hardness tester represents a significant breakthrough in metal hardness testing, thanks to its innovative Esatest® principle. This advanced hardness measurement method allows operators to take readings even in the most difficult-to-reach areas, such as interiors, cavities, joints, and gears.

Esatest® Principle: An Innovative Approach The Esatest® principle, developed by Ernst, is a revolutionary approach to hardness testing that leverages the correlation between penetration depth and changes in residual electrical resistance. This technology uses a special indenter, enriched with boron to make it conductive, that provides measurements based on electrical resistance changes induced by varying loads. This indirect method offers several advantages, such as enabling measurements with very low loads to minimize damage to finished parts and allowing tests in positions conventional instruments cannot reach.

Key Features of Esatest® Technology:

-

Measurement Capability: The system can measure across a wide range of loads, including very low ones, and display results in various hardness scales (Brinell, Vickers, Rockwell, and Super Rockwell).

-

Technology: By leveraging the conductive properties of a boron-doped diamond indenter, Esatest® technology utilizes the correlation between penetration and residual electrical resistance. The plasma-based chemical deposition method is used to create the boron-enriched diamond indenter, which enhances electrical resistance measurements.

With the ACCREDIA (ILAC MRA) calibration certificate according to DIN 50158-2, the MTR X hardness tester is a highly reliable and accurate solution for metal hardness testing.

Choose Ernst's MTR X hardness tester for your metal hardness measurement needs and experience the precision, reliability, and innovation this instrument offers.