Rockwell Hardness Testers by Cisam-Ernst: Precision, Reliability, and Innovation with AT250 D

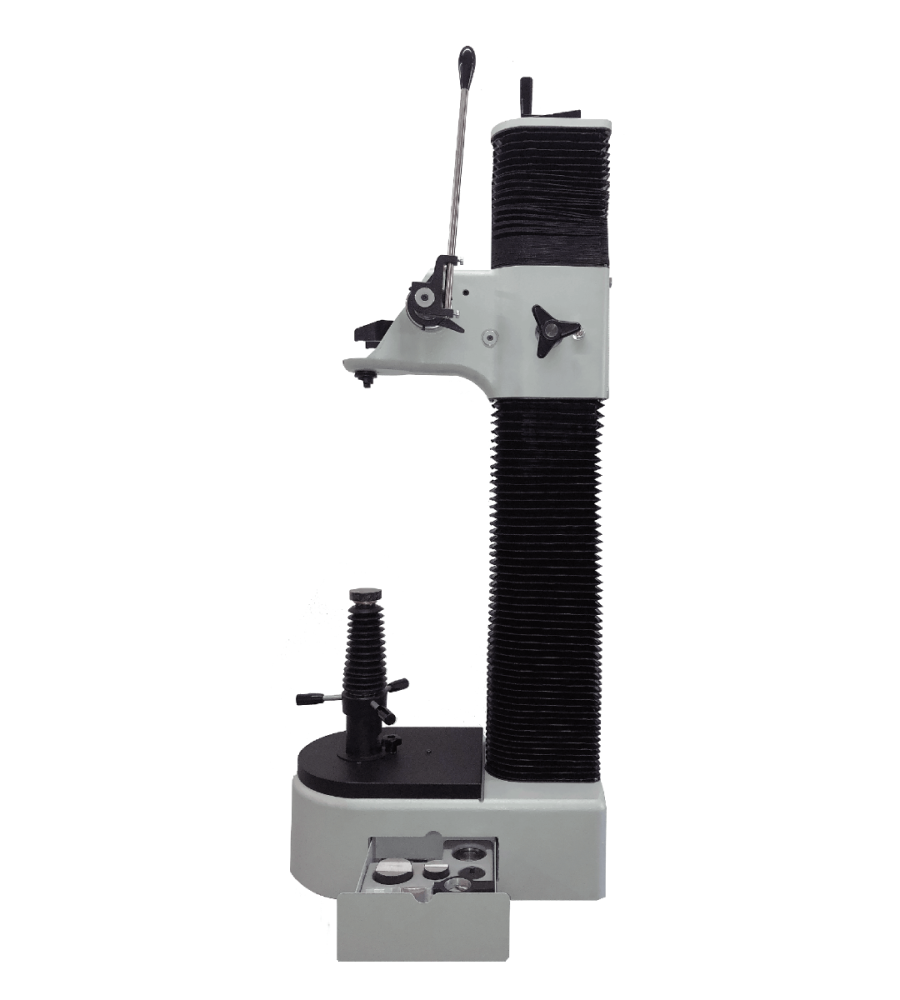

In the realm of materials engineering, Rockwell hardness testers are essential instruments for measuring material hardness. Cisam-Ernst, with its AT250 D model, embodies the evolution of this tradition, offering a cutting-edge solution that combines the precision and speed of traditional Rockwell hardness testers with electronic innovation for test data processing.

Key Features of the AT250 D Hardness Tester:

- Test Speed: The Rockwell principle allows tests to be conducted in just 2 seconds, significantly improving productivity.

- Spring-Loaded System: Provides reliable tests that comply with international standards, ensuring measurements are insensitive to material indentation and bending.

- Versatility and Precision: Available in both standard and superficial Rockwell versions, the AT250 D conducts precise tests on various materials, adhering to UNI, ISO, DIN, and ASTM standards.

- Durability and Adaptability: Resistant to harsh environments, thanks to the spring-loaded system, it maintains performance even under extreme conditions of temperature, dust, and humidity.

- Advanced Communication Technology: With a wide range of interfaces, the AT250 D enables easy sharing of measurement data, aligning with Industry 4.0 principles.

Benefits of the AT250 D:

- A 2-second test speed enhances quality control efficiency, enabling companies to handle a higher test volume without compromising accuracy.

- The spring-loaded system ensures highly reliable measurements that comply with international standards, preventing errors and ensuring product compliance with industry requirements.

- The tester's versatility and precision allow it to evaluate a wide range of materials, ensuring compliance with UNI, ISO, DIN, and ASTM standards.

- The device's durability and adaptability enable it to be used in various environments, ensuring process continuity even under challenging conditions.

- The availability of interfaces allows for easy integration of the hardness tester with digital systems, improving data management and information sharing within the company, offering a competitive advantage.

Evolution of the AT130 Model: The AT250 D line of hardness testers represents the evolution of the well-known AT130 model, a device sold in thousands of units worldwide since the 1970s. It brought significant innovation to the industry due to its ability to quickly measure the hardness of large components with a system insensitive to indentation and bending.

Commitment to Quality and Durability: Cisam-Ernst ensures the precision, reliability, and robustness of its Rockwell hardness testers through a constant commitment to design. Each device is built to deliver high performance over time, even in the most challenging environmental conditions.

Conclusion: The AT250 D hardness tester represents the perfect blend of traditional Rockwell hardness testers and technological innovation. It is an essential tool for anyone seeking a reliable and precise solution for hardness testing of materials.