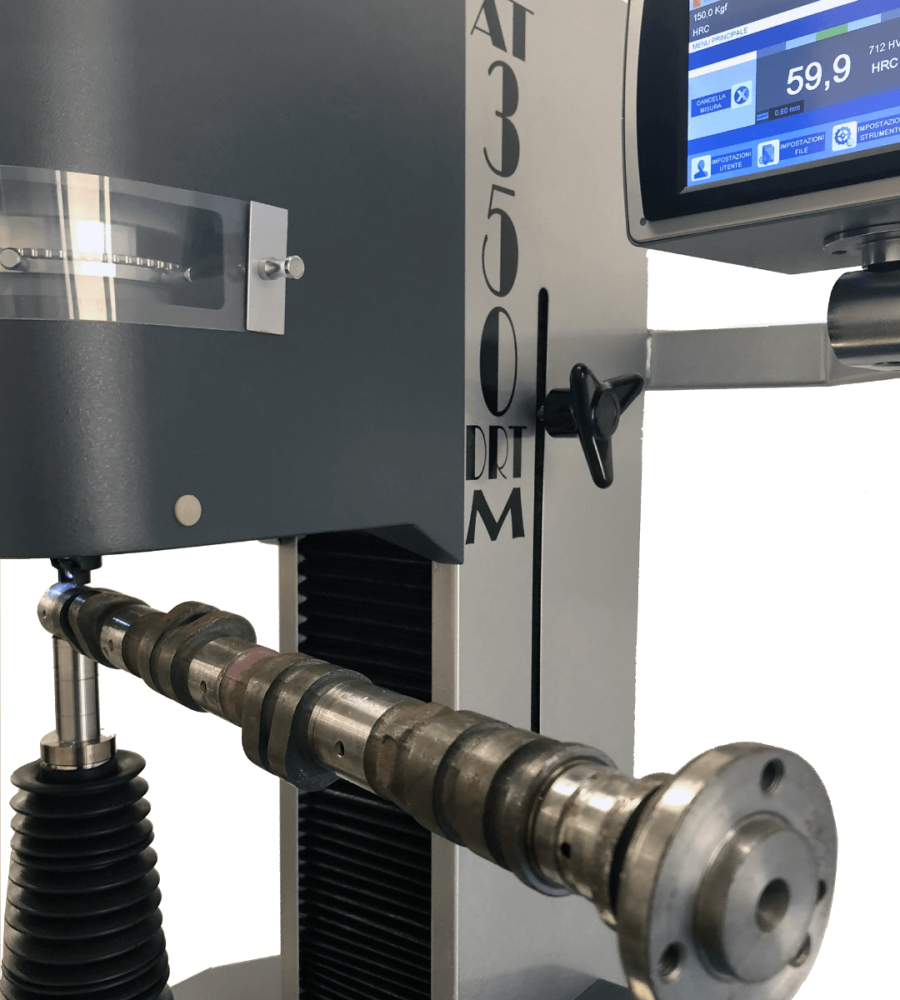

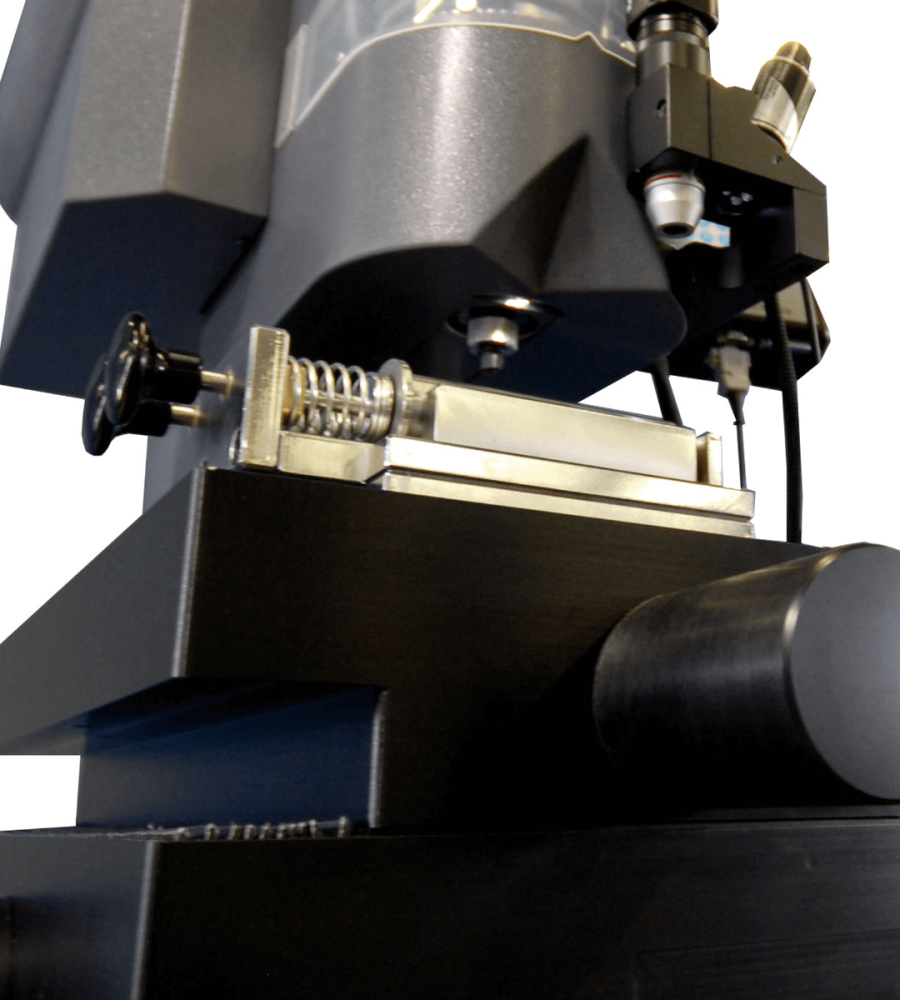

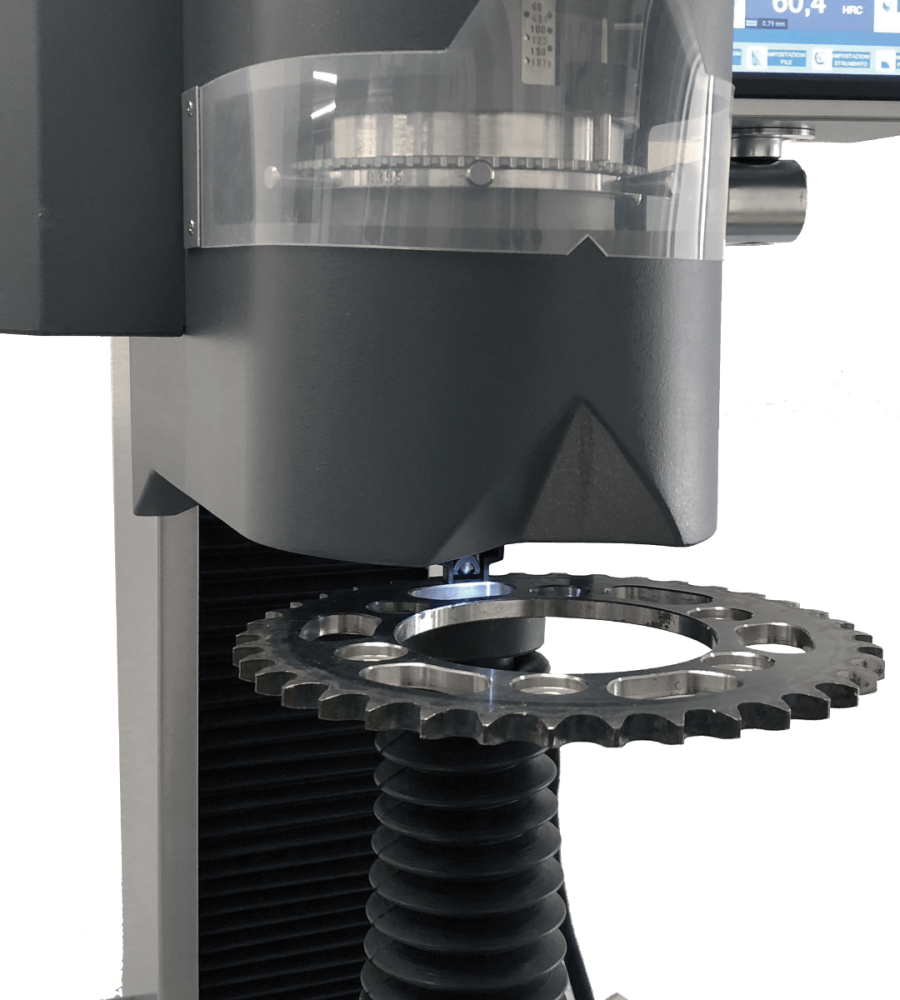

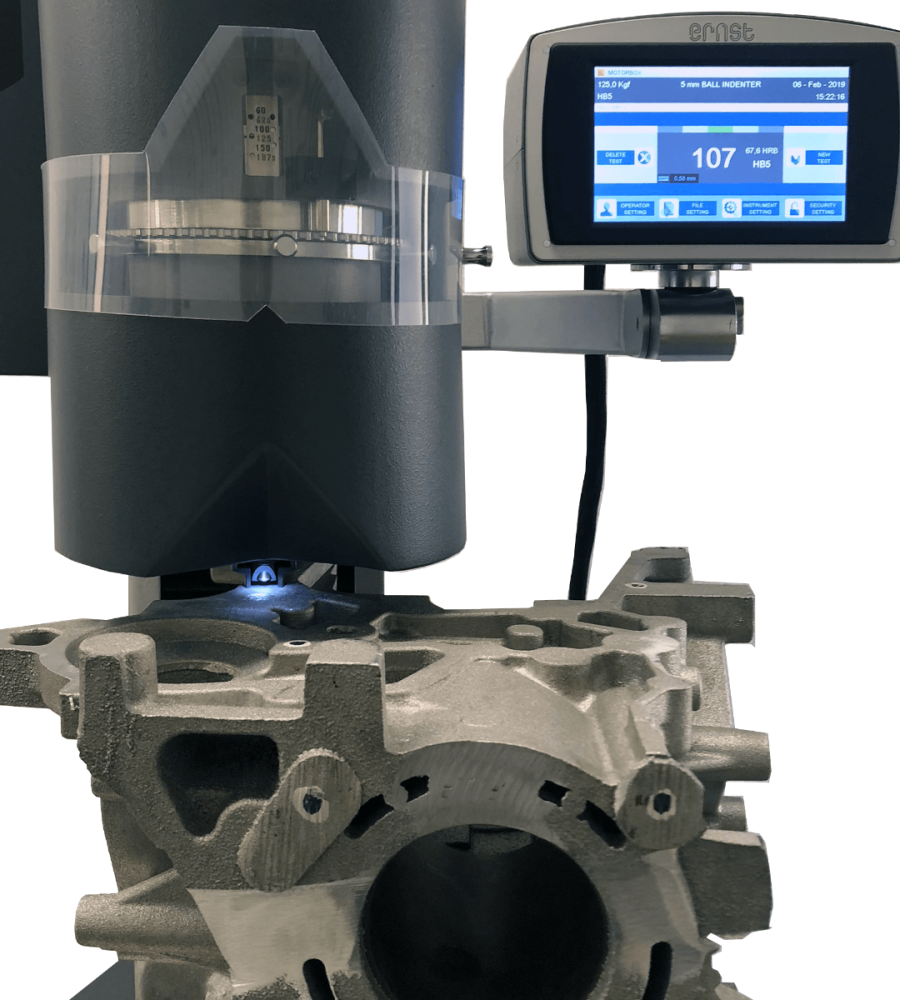

The AT350 hardness tester represents the cutting edge in hardness measurement based on the Rockwell principle. Automated and reliable, this instrument operates in accordance with EN, DIN, ISO, and ASTM standards, providing accurate results across a wide range of materials. Ideal for testing large parts and for Jominy testing, the AT350 simplifies processes with its motorized stand, adapting easily to different testing conditions.

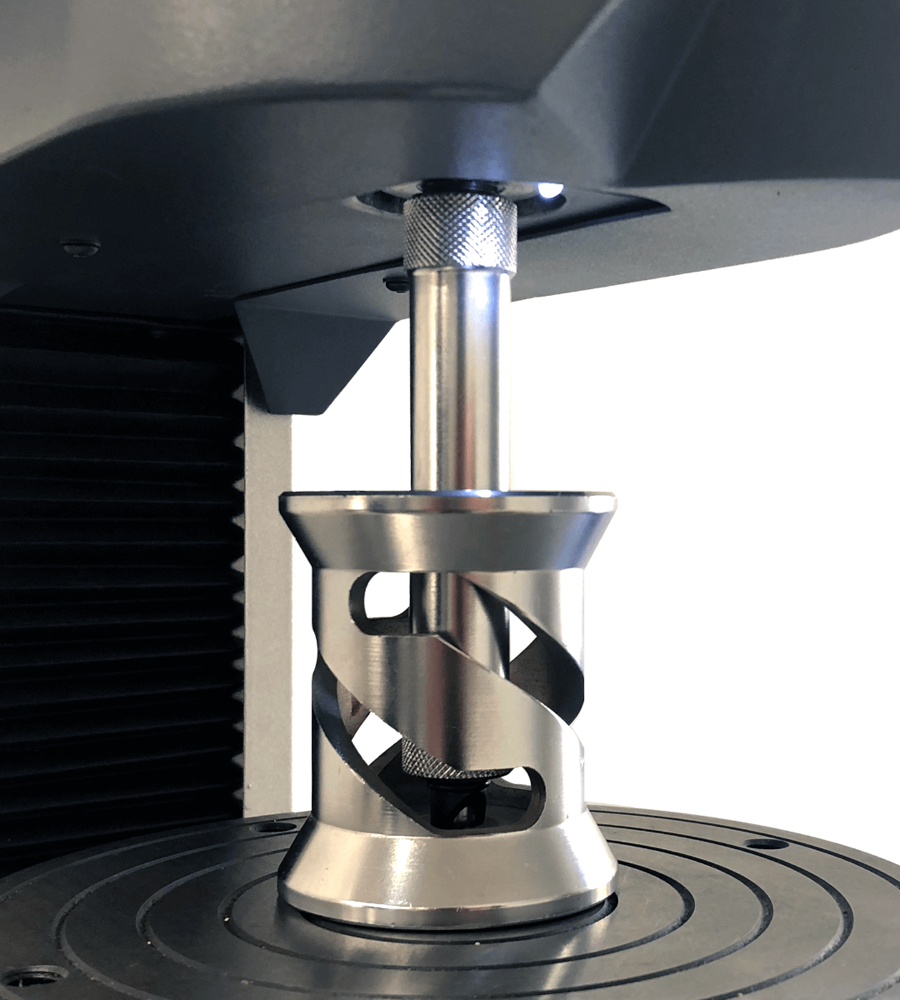

Its ability to automatically apply preload during measurements reduces the required time and minimizes errors, allowing automatic batch control without the need for an operator. With Cisam-Ernst's patented spring load system, the AT350 ensures precision and reliability even in the harshest environments, withstanding extreme temperatures, dust, humidity, and vibrations.

Thanks to Cisam-Ernst's commitment to precision and reliability, the AT350 is designed to withstand intensive use and the test of time, offering robust instruments that can maintain optimal performance over the long term.